Hultafors Ågelsjön Mini Hatchet (Free delivery use coupon FREESHIP)

$179.00

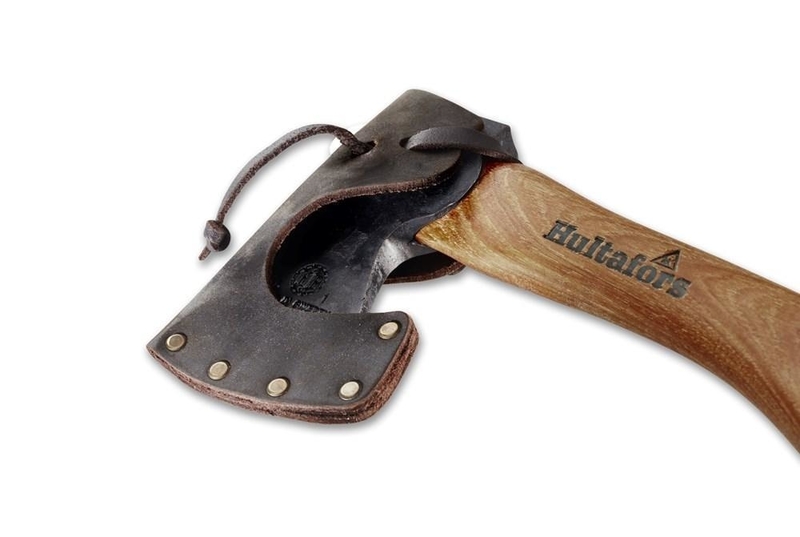

Hultafors Ågelsjön Mini Hatchet

This is Hultafor’s smallest hatchet, suitable for hiking in the mountains or in the woods. The hatchet is flexible and easy to use and it fits perfectly for diverse tasks near the campsite, such as processing firewood, and shelter building. With its short handle and light weight it is easy to pack in your backpack or attach to your belt.

This hatchet has become a favorite among those who enjoy spending time around the camp fire. The hatchet is hand forged and made from Swedish quality steel in the forge at Hults Bruk. The forging tradition goes as far back as 1697 and the steel head is struck 40 – 60 times to increase density and durability to the head. The hardening method leaves a clear hard zone within which the axe can be sharpened whilst not detracting from the strength of the edge.

The handle is made from American grown Hickory, a strong and flexible wood.

The axe is named after the nearby lake Ågelsjön where the water needed to run the waterwheel for the forge, was once taken.

Thanks to the quality and craftmanship of this axe a lifetime warranty on the head is offered.

It has a shaft length of 235mm, has a head weight of 500g and a toatl weight of 775g. It comes standard with a leather sheath. The Hultafors Ågelsjön mini hatchet is sharpened by hand not machine, so it is exceptionally sharp. It comes nicely presented in its own gift box. It makes a very unique present for someone special.

Hults Bruks has forged axes for over 3oo years. Hults Bruk was originally founded in 1697 in the Hulta Valley in Southeastern Sweden. Forging by hand began with nails for shipbuilding and iron bars. In 1870 axes became a major part of Hults Bruk’s production. Today Hults Bruk is a mixture of the new and the old, but the basic culture has not changed over the years.

The blacksmith’s workshop is the heart of Hults Bruk. At every axe-forging machine there are two people working, one on either side. The work starts by placing a piece of steel in an oven, to make it soft enough to reshape. When the heated steel reaches the correct color, the two blacksmiths start to forge. They form the head by hand, each after the other, step by step. When they are satisfied with the shape of the head they finish it by stamping the well known “HB” mark into the axe head.

It is important that the edge of the axe is stong and solid. The hardening master is responsible for giving the edge the correct hardness and ensuring that it will not be brittle. This is done by heating up the axe head and cooling it rapidly. The rough forging surface gives each axe head its own special character, which makes each axe unique. The fixing of the handle is also done by hand with both a wooden and steel wedge.

FREE postage Australia wide. For FREE delivery use coupon FREESHIP at checkout.

VC Traders is an official Hultafors dealer.

Enjoy this video showing the forging of axes by hand.

Availability: 12 in stock (can be backordered)

You may also like…

-

Gransfors Bruk

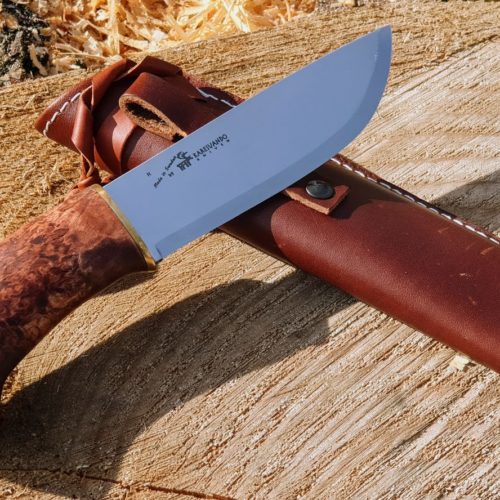

Gransfors Bruk 473-R Small Carving Hatchet (Free delivery use coupon FREESHIP)

$289.00 Read more -

Gransfors Bruk

Gransfors Bruk 420 Small Forest Axe (Free delivery use coupon FREESHIP)

$279.00 Add to cart