Hultafors Ekelund Hunting Axe

$254.00

Hultafors Ekelund Hunting axe.

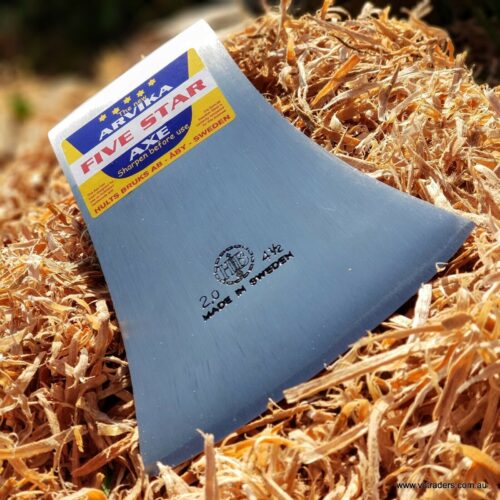

Hand forged in Sweden using traditional methods in use since 1967. At Hults Bruk in Ostergotland the axe heads are forged from Swedish axe steel of a consistently high quality.

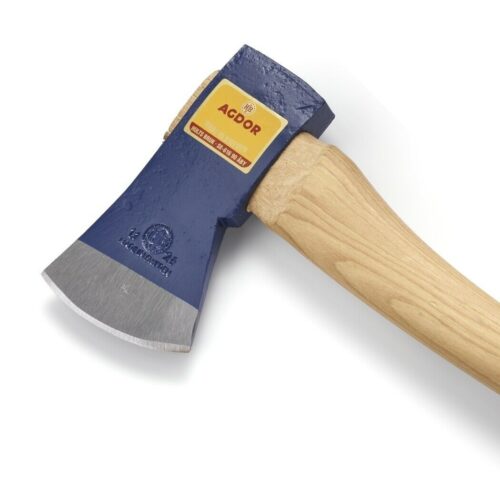

The handle is made from American grown Hickory, a strong and flexible wood.

With its ground neck and medium weight head the Ekelund Hunting Axe is ideal for easier forestry work as well as for skinning game with great precision. This makes it your perfect hunting partner. Like all Hultafors axes, it is hand forged and made from Swedish quality steel at Hults Bruk, according to their forging tradition since 1697.

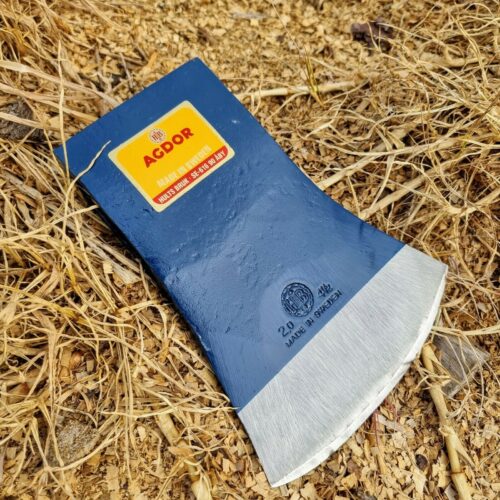

As part of the head forging process, the steel axe head is struck 40-60 times, thereby increasing its density and resulting in great durability. The hardening method leaves a clear hard zone within which the axe can be sharpened whilst not detracting from the strength of the edge.

The name of the hunting axe comes from Gunnar Ekelund, the squire who, inspired after a trip to the USA, initaited axe production at a larger scale in 1870-75. Today, just like when they started , their work is characterised by a great pride in the craft.

Thanks to the quality and craftmanship of the axe, Hultafors is able to offer a lifetime (50 year) warranty on material and workmanship defects on the head of the axe.

It has a shaft length of 500mm a head weight of 850g and overall weight of 1210gms. It comes standard with a leather sheath, cardboard presentation box, Hultafors axe booklet and the warranty paperwork. It is sharpened by hand not machine, so it is exceptionally sharp. The Hunters is perfect hunting duties and light firewood or kindling work. It is designed for tradesman, hunters, farmers and craftsmen. It makes a very unique present for someone special.

Hults Bruks has forged axes for over 3oo years. Hults Bruk was originally founded in 1697 in the Hulta Valley in Southeastern Sweden. Forging by hand began with nails for shipbuilding and iron bars. In 1870 axes became a major part of Hults Bruk’s production. Today Hults Bruk is a mixture of the new and the old, but the basic culture has not changed over the years.

The blacksmith’s workshop is the heart of Hults Bruk. At every axe-forging machine there are two people working, one on either side. The work starts by placing a piece of steel in an oven, to make it soft enough to reshape. When the heated steel reaches the correct color, the two blacksmiths start to forge. They form the head by hand, each after the other, step by step. When they are satisfied with the shape of the head they finish it by stamping the well known “HB” mark into the axe head.

It is important that the edge of the axe is stong and solid. The hardening master is responsible for giving the edge the correct hardness and ensuring that it will not be brittle. This is done by heating up the axe head and cooling it rapidly. The rough forging surface gives each axe head its own special character, which makes each axe unique. The fixing of the handle is also done by hand with both a wooden and steel wedge.

VC Traders is an official Hultafors dealer.

FREE shipping Australia wide. For FREE postage use coupon FREESHIP at checkout.

Availability: 2 in stock (can be backordered)

You may also like…

-

Gransfors Bruk

Gransfors Bruk 420 Small Forest Axe (Free delivery use coupon FREESHIP)

$299.00 Add to cart